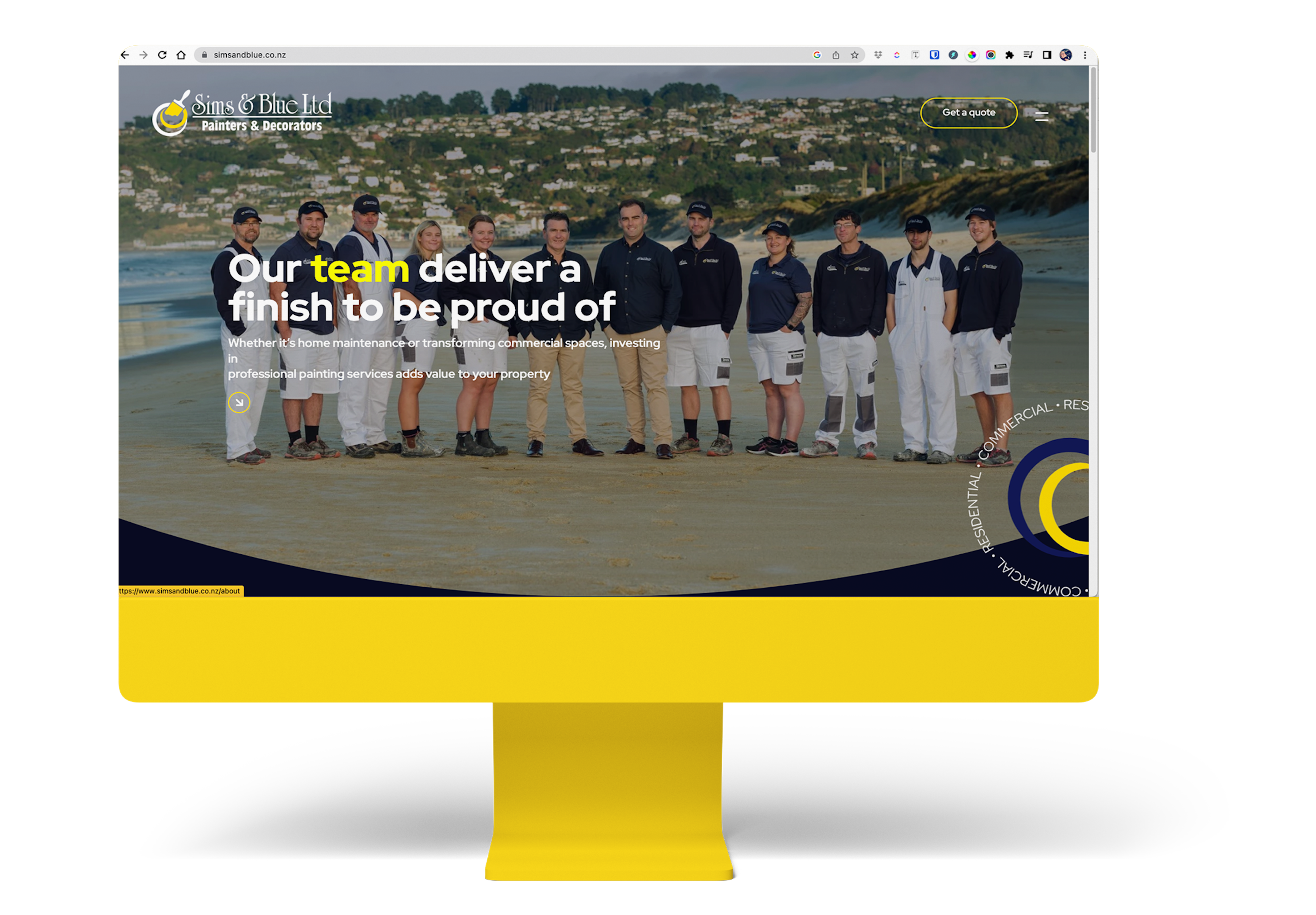

Turboweb worked with Nathan at Sims and Blue to design and build a flagship website to get them back in the running to win 'Best Website' at the Master Painters awards.

Turboweb Template sites are built using our platform, meaning that you retain the powerful content management and search engine optimisation that Turboweb customers have come to love!

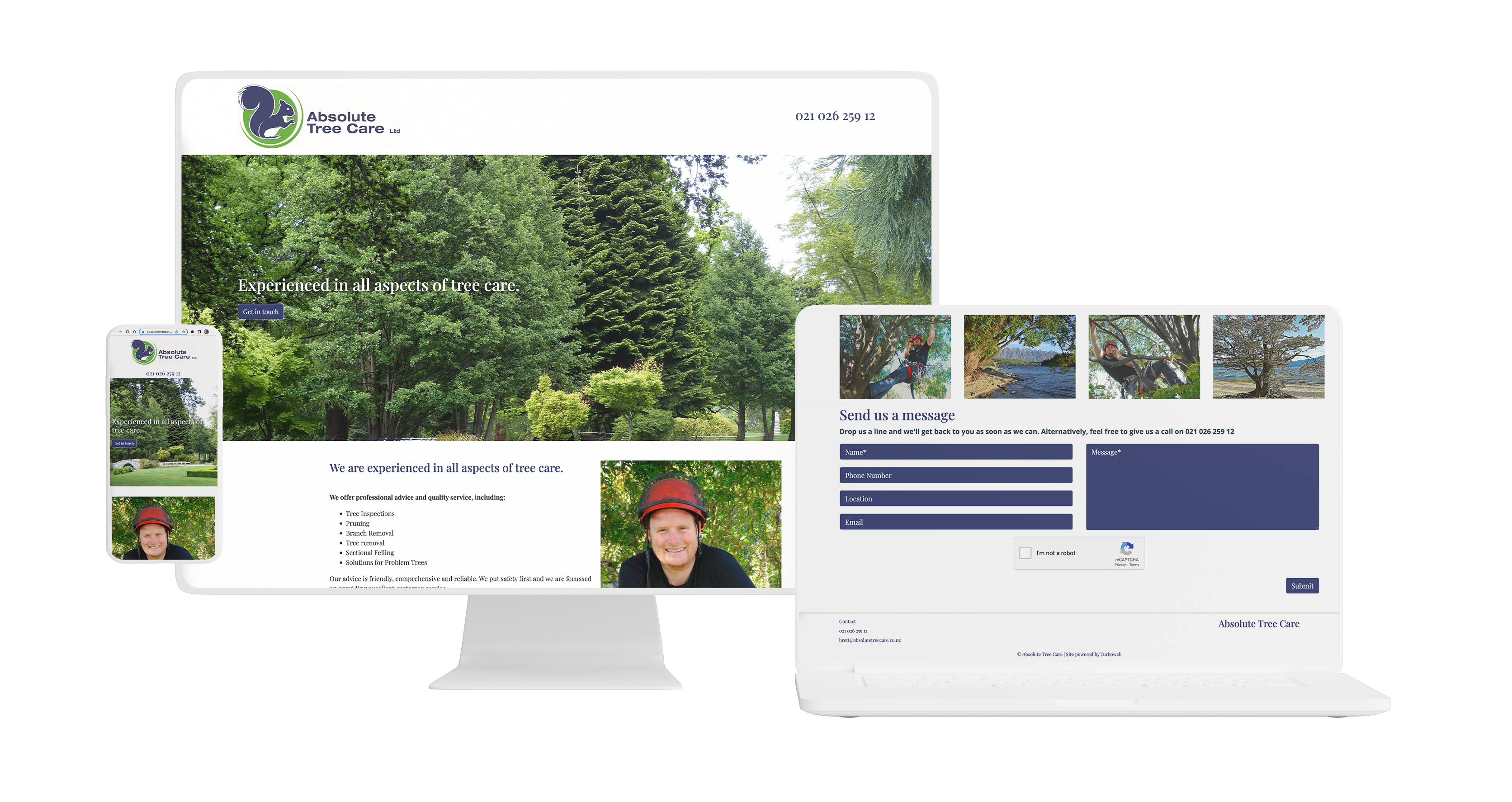

Absolute Tree Care just wanted to replace an old static SinglePage site they had at the lowest cost possible. Check out what we whipped up for Brett on the fly.

Starting something can be daunting but solid branding sets a firm foundation for any organisation. Turboweb designers worked with Aroha Kaikorai Valley Trustees to come up with a logo that felt right, it represents our awa (stream) and how much we love The Valley.